LCD Optical Bonding

LCD Optical Bonding

ELIMINATE OUTDOOR VISIBILITY ISSUES FOR GOOD.

Increase TFT AMLCD readability-at-a-glance capability with optically bonded TFT displays from AbraxSys. With this service, our engineers combine technologies like LED backlight enhancements and optical coatings with monitors and touchscreens to meet your human-interface requirements. While standard LCDs are fine for most indoor applications, they are challenged in outdoor and extreme environmental applications. Under these circumstances, commercial displays are all but useless. The choices are to reduce display washout, increase brightness, or both. Although OEM display manufacturers don’t focus on providing solutions for these markets and applications, AbraxSys does.

AbraxSys high-performance optically bonded displays are ideal for heavy-duty outdoor or industrial environments where top performance is required. Our in-house optical bonding facility provides proven quality systems, extensive internal testing, verification capabilities, a certified clean room, and other environmental controls.

LCD Outdoor Viewability Problem

The traditional method of making an LCD viewable outdoors (in bright ambient light) is to increase the intensity of the backlight to approximately 750 to 1000 cd/m2 (nits). This adjustment makes the viewable light more pronounced than the reflected ambient light by shifting the display viewing to a higher luminance level. This approach has some problems if it’s the only action taken. Increasing the backlight brightness raises both black and white luminance, reducing the contrast ratio (all other things unchanged). Lower contrast makes the display harder to read.

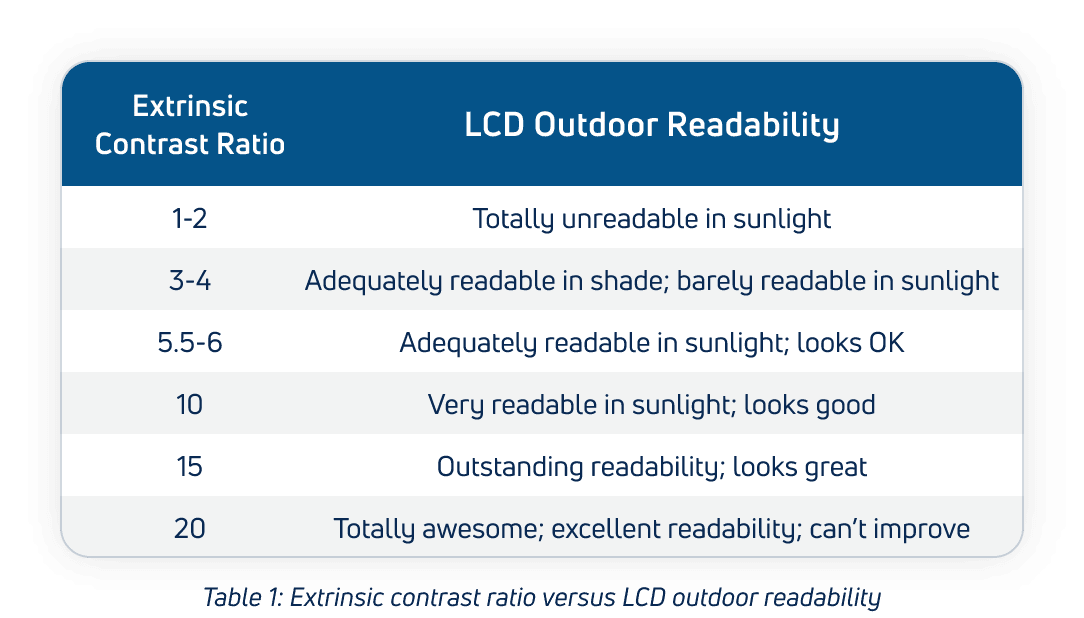

The real problem with LCD outdoor viewability is contrast, not brightness. Contrast is the ratio of the white level to the black level. Said another way, a display’s contrast ratio is the difference in light intensity between the brightest white pixel and the darkest black pixel. In this situation, we’re talking about “extrinsic” contrast, meaning a reading taken from a distance that accounts for ambient light and reflections. (The contrast ratio in a display’s specifications sheet is “intrinsic” contrast, measured at the screen’s surface in a dark room.) Increasing the extrinsic contrast ratio improves outdoor viewability. Some rule-of-thumb values for extrinsic contrast are shown in Table 1 below.

The real problem with LCD outdoor viewability is contrast, not brightness. Contrast is the ratio of the white level to the black level. Said another way, a display’s contrast ratio is the difference in light intensity between the brightest white pixel and the darkest black pixel. In this situation, we’re talking about “extrinsic” contrast, meaning a reading taken from a distance that accounts for ambient light and reflections. (The contrast ratio in a display’s specifications sheet is “intrinsic” contrast, measured at the screen’s surface in a dark room.) Increasing the extrinsic contrast ratio improves outdoor viewability. Some rule-of-thumb values for extrinsic contrast are shown in Table 1 below.

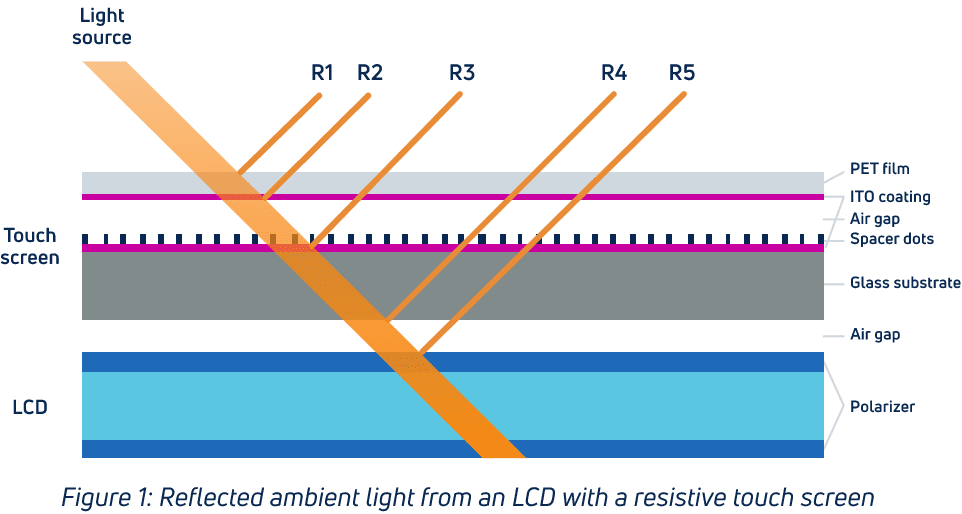

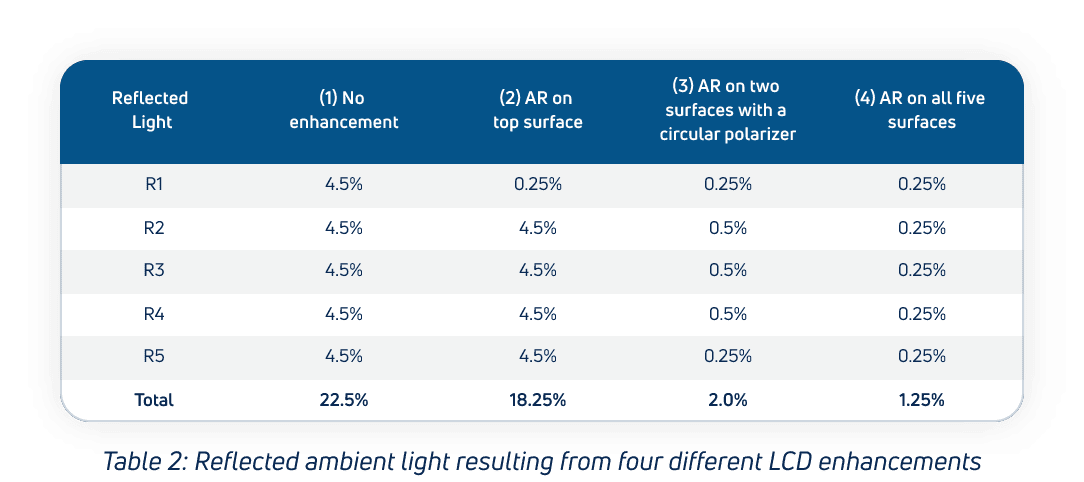

Figure 1 shows the reflected light from an LCD with a standard resistive touch screen, and Table 2 shows four enhancement cases.

Explore the Benefits of AbraxSys LCD Optical Bonding

- Improves contrast by eliminating mismatched reflective layers

- Improves readability without increasing backlight wattage

- Increases sunlight readability by up to 400%

- Increases shock and vibration resistance

- Strengthens the overall integrity of the LCD

- Increases scratch resistance by up to 300%

- Enables resistance to extreme temperatures

- Eliminates “greenhouse” and isotropic effects

- Reduces specular and diffuse reflections

- Reduces power consumption in battery-powered devices while enhancing readability

- Certified cleanroom and environmental controls

- Fast, responsive manufacturing in the USA

Talk to a Monitor Expert

Not sure exactly which services are right for you? Need help deciding whether to go with a ready-to-ship model or something custom? Don’t hesitate to contact an AbraxSys associate anytime for more information about our services and guidance on the best solutions to any ruggedized and sunlight-readable monitor needs.